| Sign In | Join Free | My howtoaddlikebutton.com |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My howtoaddlikebutton.com |

|

Brand Name : Custom LOGO

Model Number : HW-638

Certification : ISO9001

Place of Origin : China

MOQ : 1set

Price : 2000-10000USD

Payment Terms : T/T , Paypal

Supply Ability : 40sets/month

Delivery Time : 25-40days

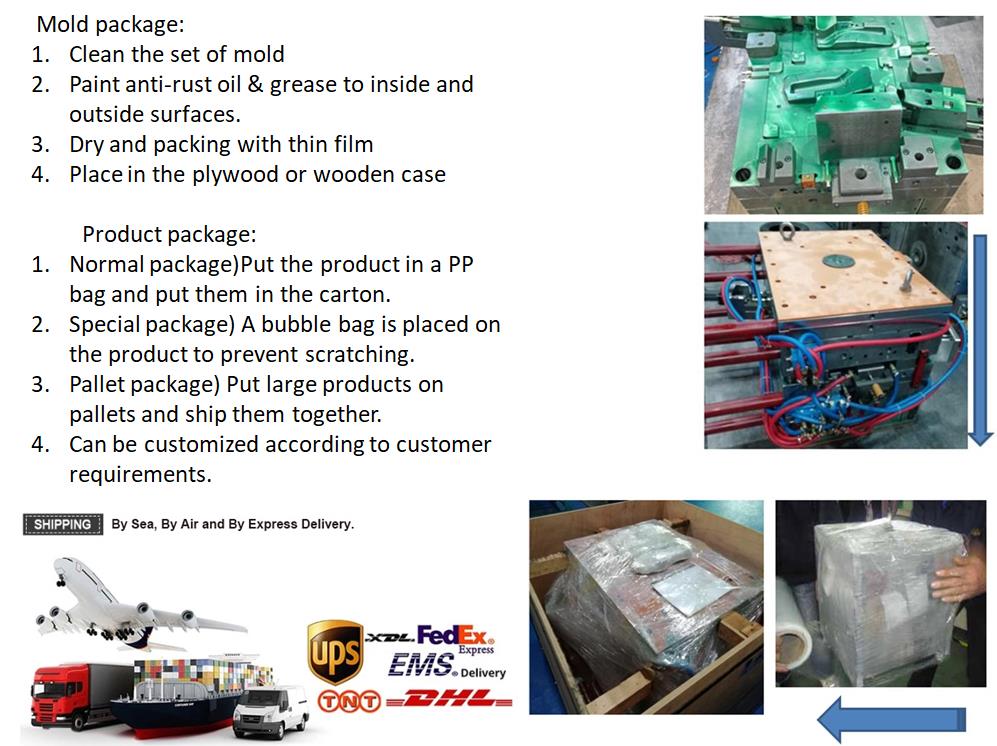

Packaging Details : wood carton, as customer requested

Name : Plastic injection Tooling

Life Time : 300k~1000k Times

Surface Requirement : Smooth, Polishing, Painting, SandBlasting, Electroplate, Silk-screen, Laser Etching, Anodizing,Brushing

Plastic Material : ABS,PMMA,PA66,PETS,PC,TPU,PS, PBT, ect.

Mould Base type : LKM, FUTA, HASCO, DME, TSMP, Or as per customer’s requirement.

Hardness of the steel : 20~48 HRC

Plastic Part Diameter : 5-1000mm,or customized

Mold cold runner : Single or Multi cavity

Single & Multi Cavities Plastics Injection Mold With 718H Steel Material

1000k Shots Multi Cavity Plastic Injection Mold for Bottle Cap

We offer design,mold build, injection molding, mold repair, tool and die, wire/sink EDM. Our complete portfolio provides you with a high quality resource supported by on-time delivery at a competitive price. Please provide your e-mail contact information, and I will be glad to send you information on our manufacturing capabilities.

| Product name | Multi cavity hot runner injection mould supplier |

| Mould Material | P20,P20H,718,718H,738,738H,2316,M300,S136,S136H,NAK80,CR12,CR12MOV,SKD11,DF-2,SKS3,D2,SLD,DC53,H13,SKD61,2344,8407,HD,8418,FDAC,M2,SKH-9,SKH-51,M35,M42,ASP23 |

| Main Technology | Milling, grinding, CNC, EDM, wire cutting, carving, EDM, lathes, surface Finish, etc. |

| Base material | P20, 2738, 2344, 718, S136, 8407, NAK80, SKD61, H13 |

| Product Material | ABS,PP,PC,PA6,PA66,TPU,POM,PBT,PVC,HIPS,PMMA,TPE,PC/ABS, TPV, TPO,TPR,EVA,HDPE,LDPE,CPVC,PVDF |

| Main Technology | Milling, grinding, CNC, EDM, wire cutting, carving, EDM, lathes, surface Finish, etc. |

| Equipment | CNC, EDM, Cutting off Machine, plastic machinery, plastic part, etc |

| Mould Cavity | One cavity, multi-cavity or same different products be made together |

| Runner System | Hot runner and cold runner |

| Finish | Pitting the word, mirror finish, matte surface, striae |

| Mould Life | 300-500K shots |

| Mould Precision | +/-0.05mm--+/-0.1mm |

| Producing Process | Audit drawings - mold flow analysis - design validation - Custom Materials - mold processing - core processing - electrode machining - Runner system processing - parts processing and procurement - machining acceptance - cavity surface treatment process - complex mode Die - The entire mold surface coating - Mounting plate - mold sample - sample test - sending |

Our Service

1, Product Design

We Provide Product Design Service as Customer's Request.

2, Mold Design

We will communicate &exchange the opinion with customers during Mold Design

3, Mold Making

Start to manufacture, we will send photos to show tooling process.

4, Provide the sample

Once the sample finish, we will send the sample to customer confirm

5, Mass Production

After customer confirmed the sample, we will start mass production plastic products.

6, Assembly

We Also Provide Assembly Service for Our Customer.

Painting & Coating

We can provide coating and rubber coating service for your customers.

7, Printing

We Also Provide Silk Screen Printing, Pad Printing, Heat Transfer Print Service.

8, Packaging Box

We also make the packaging box as customer request.

Customer Visiting

Packing and Shipping

Howe company Advantage:

1. Competitive price

2. Continuance service and support

3. Diversified rich experienced skilled workers

4. Custom R & D program coordination

5. Application expertise

6. Quality reliability and long product life

7. Mature,perfect and excellence ,but simple design

|

|

1000k Shots Multi Cavity Plastic Injection Mold for Bottle Cap Images |